Description

| Manufacturer | 3M |

|---|---|

| Brand | 3M Abrasives |

| Main Category | Abrasives |

| Packaging | 1EA, 5EA/CT |

| Weight | 0.02 lb |

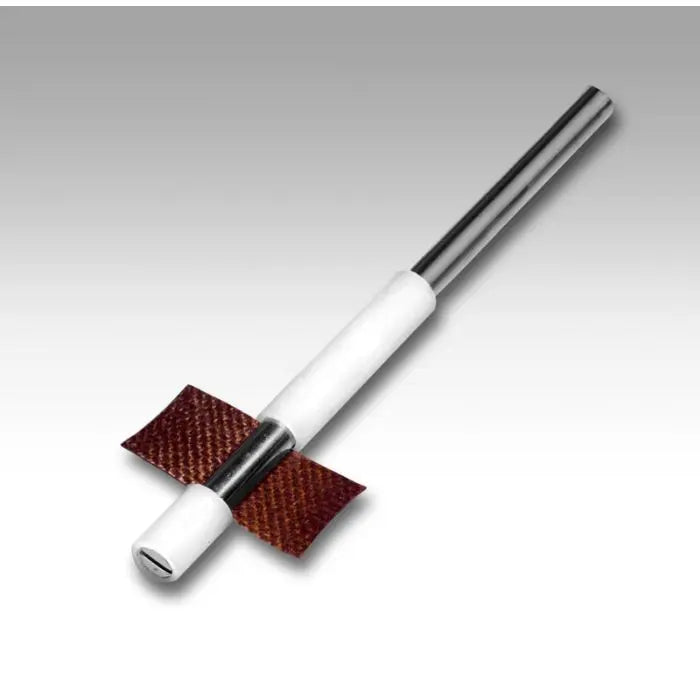

Our 3M™ Roto Peen Flap Assembly, made with a flap and mandrel, was designed using captive shot flap technology. To create this unique and portable assembly, we adhered tungsten carbide shot to flexible flaps using high strength resin. Two flaps are bonded together with a special adhesive for easy placement in a flap mandrel.

Peening, a cold working process for metal, applies repeated stress to the material's surface and strengthens it through compression. The peening method helps improve the material's ability to resist fracture, fatigue and stress corrosion cracking. In traditional shot peening methods, the work surface is sprayed with cast steel shot. While this method is also effective, it has a tendency to dirty the operator’s environment by releasing debris. Additionally, the tools required for this method limit the spaces where an operator can peen.

Our 3M™ Roto Peen Flap Assembly does not require a sandblaster or the accompanying abrasive materials, as the tungsten carbide shots are already adhered to the flap. The benefits of this unique construction are twofold. First, peening is cleaner because debris is not released as the flaps abrade the surface. The captive shot flaps provide a more precise method than loose shot "blasting." Second, the assembly is portable, making it more convenient for operators to use.

Flap/mandrel assemblies are especially effective for precision in service rework, manufacturing, repair of small areas and peening holes. The 3M™ Roto Peen Flap Assembly comes in three sizes and allows for peening a variety of surfaces and radii area. Plus, the uniform TC 330 shot size contributes to consistent results. As the part is peened, a compressive residual stress is created. It’s a non yielding layer that increases the material’s ability to fight fatigue, stress and fracturing.

Flap rotation speed is the most important factor affecting peening intensity. Increasing the speed of rotation increases the intensity. Conversely, decreasing the speed decreases the intensity. To insure uniform peening coverage, operators should use a circular or oscillating motion over the entire area.

TOP BRANDS

Shop the most trusted safety brands at Enviro Safety.

PRODUCT SPECIALISTS

Got a question? Call and ask one of our trained Product Specialists.

FAST EASY SAVINGS

Get what you need. Save time and money. Let's do this!

CUSTOMER SERVICE

Yes, we answer the phone and reply to email. We're here for you!

CORPORATE ACCOUNTS

Setup an online account. Apply for credit. And more.

Recently Viewed

- Opens in a new window.