Why 3M Fall Protection

3M has long been a leader in industrial safety and when it comes to working at heights, their DBI-SALA and Protecta brands set the standard. With decades of innovation, rigorous testing and a wide product range, 3M fall protection solutions help keep workers safe from residential rooftops to industrial tower maintenance.

Working at Heights: Hazards & Solutions

Working at height means being in any location above another level where a fall could cause injury. This includes ladders, scaffolding, roofs, edges or openings in floors or walls.

You are working at height if you are:

- Above ground or another level

- Near an edge

- Near an opening or fragile surface

Leading Edge/Sharp Edges

Fall Clearance

Dropped Objects

Understanding the ABCDs of 3M Fall Protection

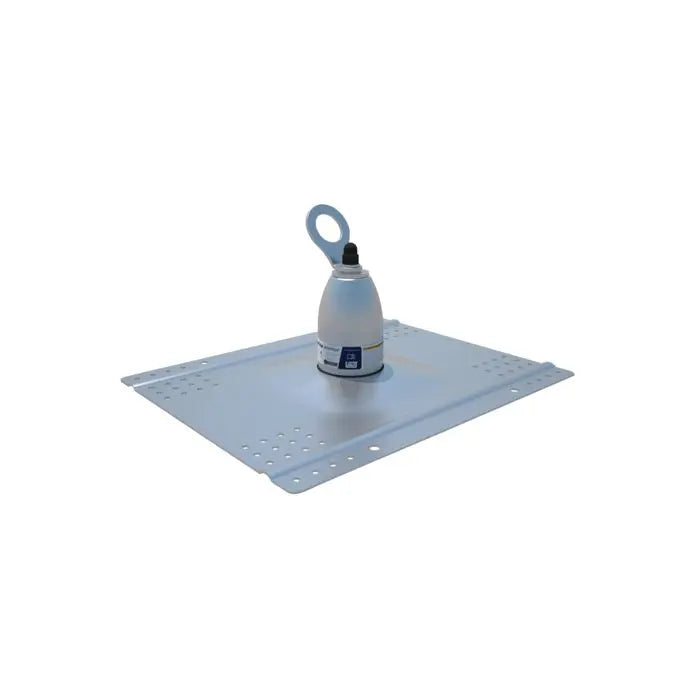

A - Anchors

Anchors are secure attachment points in a fall protection system designed to support the forces of a fall. They connect to equipment like lanyards, lifelines or SRLs and must be strong, properly placed and suitable for the work environment. OSHA requires each anchor to support 5,000 lbs per worker or be designed by a qualified professional.

What kind of anchor do I need?

Anchorage Connectors

Horizontal Lifelines

Shop Anchors

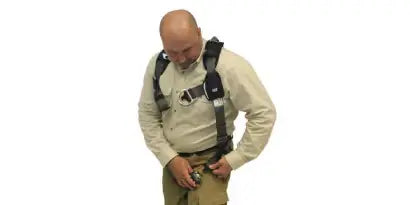

B – Body Support (Harnesses)

Body support equipment keeps workers secure, supported and in a safe position during and after a fall. Comfort, proper fit and ease of use are essential, especially since harnesses are worn for long periods.

General Fall Arrest

Ladder Climbing Harness

Work Positioning Harness

Confined Space Harness

Descent & Suspension Harness

Shop Safety Harnesses

C – Connectors

Connectors link the worker’s harness to the anchor point. The right connector ensures safety, mobility and proper fall clearance for the specific job environment.

What kind of connector do I need?

Lanyards

Self-Retracting Lifelines (SRLs)

Shop Lanyards

Shop SRL's

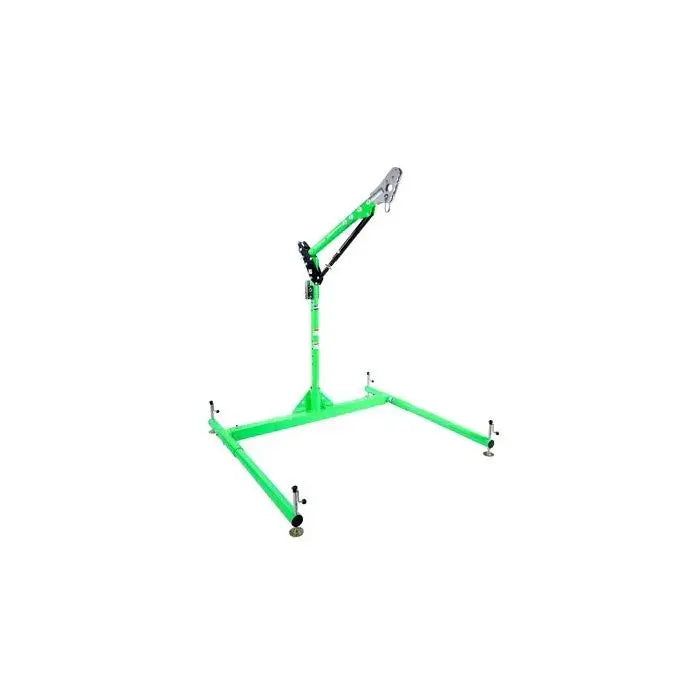

D – Descent & Rescue

Every workplace at height needs a solid rescue plan. Descent and rescue systems allow workers to evacuate themselves or be retrieved quickly and safely after a fall.

What kind of descent and rescue system do I need?

Rescue & Descent Devices

Confined Space Entry & Retrieval

Shop Descent & Rescue

Fall Protection for Tools

Working at height isn’t just about protecting workers from falls—dropped tools can also injure people below and damage equipment. Fall protection keeps you safe, while dropped object prevention protects everyone around you.

Common Dropped Object Hazards

Dropped objects can happen when:

- Tools are left near edges

- Items are stored in open pockets, bags or pouches

- Wind or movement knocks tools loose

Shop Fall Protection for Tools

How 3M Fall Protection Ensures Compliance with OSHA & ANSI Regulations

3M fall protection products are built to meet or exceed the strict requirements of ANSI Z359, OSHA 1910 and OSHA 1926 standards. Every harness, anchor, SRL and connector is engineered, tested and certified to keep workers safe at height.

OSHA (Occupational Safety and Health Administration)

OSHA sets legally required workplace safety regulations.

For fall protection, OSHA:

- Requires fall protection at 6 ft in construction and 4 ft in general industry

- Defines mandatory equipment requirements

- Establishes anchor strength rules (5,000 lbs per worker or engineered system)

- Enforces compliance with fines and penalties

If you’re on a jobsite, OSHA compliance isn’t optional.

ANSI (American National Standards Institute)

ANSI creates voluntary but highly trusted equipment standards, like the ANSI Z359 series, which guide:

- How fall protection equipment must perform

- How it should be tested

- How systems should be used safely

While voluntary, ANSI standards:

- Are widely recognized across construction & industrial worksites

- Often influence or complement OSHA regulations

- Are required by many contractors and safety programs

How to Wear a Body Harness

Inspect the Harness

Check for cuts, burns, damaged hardware or missing labels. Do a full inspection every 6 months.

Slip On the Harness

Hold by the D-ring, untangle straps, undo buckles and put it on like a jacket.

Position the Sub-Pelvic Strap

Adjust shoulder straps so the sub-pelvic strap sits right under the buttocks and both sides are even.

Buckle the Leg Straps

Bring straps between the legs, buckle them and tighten flat-hand tightness is ideal.

Adjust Chest Strap & Waist Belt

Chest strap should sit mid-chest; shoulder straps stay vertical. Buckle and flatten the waist belt.

Final Fit Check

Tighten everything evenly. The harness should be snug, secure and comfortable.

Frequently Asked Questions

Fall protection gear doesn’t have a universal “expiration date” but it must be removed from service if it shows signs of damage, fails inspection or has been involved in a fall. Always follow the manufacturer’s inspection guidelines and your company’s safety policy.

Yes as long as the equipment passes a full inspection and has not been involved in a fall. Any harness, lanyard or SRL that has arrested a fall must be immediately removed from service. Always inspect for wear, cuts, corrosion, broken stitching or missing labels before reusing.

Permanent anchors can be reused if inspected and approved. Some temporary anchors are single-use only. Always follow manufacturer guidance.

A lanyard is a fixed-length connector, while an SRL (Self-Retracting Lifeline) automatically extends and retracts to minimize free fall distance and reduce impact forces.

Choose based on your task:

- General Use: Standard fall arrest harness

- Ladder Climbing: Front D-ring

- Positioning: Side D-rings

- Confined Space: Shoulder D-rings

- Suspension/Descent: Front D-ring with additional support points

Most systems are rated for users up to 310 lbs (140 kg) including tools, but many 3M systems are designed for higher capacities. Always check the product specifications.

Yes. OSHA requires workers to be trained in proper use, inspection and hazards of fall protection systems before working at height.

It’s a safety system that prevents tools or equipment from falling and injuring people below. This includes tool tethers, buckets and attachment points.